How much can software-based risk assessments save your business?

It makes sense to calculate just how much money you can save with risk assessment software before you sign up. So using our risk assessment productivity case study, we’ve calculated the savings for a business to be between $72.25 and $116.15 per worker, per month. Not too shabby. Under plant conditions these savings increase to between $144.50 and $231.63. Even better.

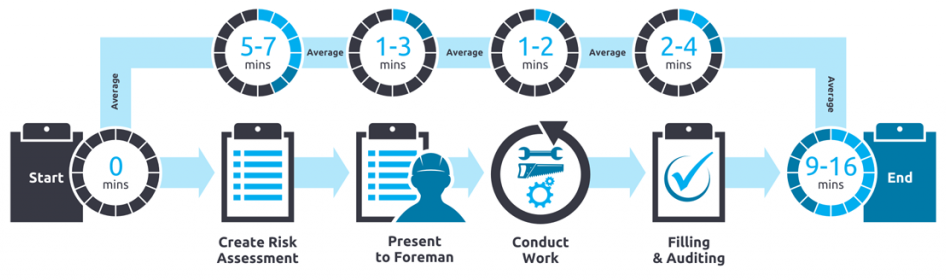

So far we’ve discerned that risk assessment forms take around 9-16 minutes to complete whereas with SafeWorkPro’s software alternative, the risk assessment workflow only took 4-8 minutes. That’s a time saving of 50 to 55 per cent! To get a better idea of the steps behind these savings, take a look at the below diagram that shows time-cost associated with the paper-based method.

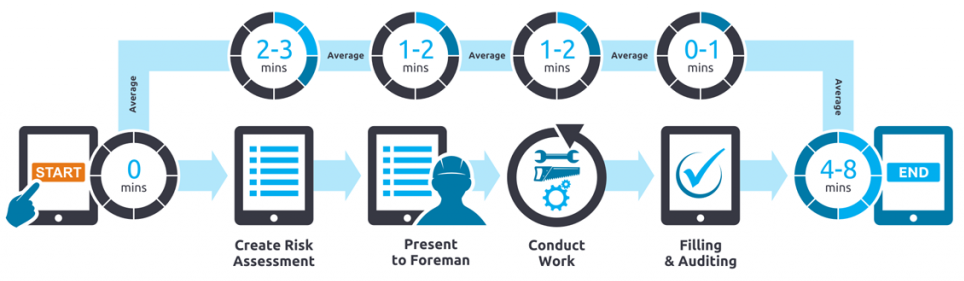

The same workflow is used when using a software-based process compared to a paper-based process but the average time a reduced. From this we can determine a time saving per worker. The next diagram shows the average time spent on software-based risk assessments.

As you can see, risk assessment software offers massive time savings and as the old saying goes ‘time is money’. But before we get into the specifics of how we came to these figures it should be noted that the savings below do not take into account the cost of safety management software. Nonetheless the results are still great.

Let’s begin by calculating the time spent completing the risk management procedure for an individual worker every month.

Avg job time = 4 to 8 mins

Avg jobs per month = 20 jobs

Avg job time x avg jobs per month

= 4 to 8 mins x 20 jobs

= 1.3 to 2.6 hours per month

Depending on where the invoices and time sheets are considered, the costs will be on either the contractor’s business or the plant they work for. In these following calculations we include both costs to show a comparison but when you are doing your own cost analysis you must consider which business will be liable.

The average cost of a worker is:

Avg cost to business = $42.50/hour (Hour much you pay your workers)

Or

Avg cost to plant = $85/hour (How much you charge for your workers)

Therefore to calculate the amount of money spent in a month for a single worker:

Avg cost to business x hours per month

= $42.50 x 1.3 to 2.6

= $55.25 to $110.50 per month per worker

Or

Avg cost to plant x hours per month

= $85.00 x 1.3 to 2.6

= $110.50 to $221.00 per month per worker

What about the annual cost? The figures taken from our survey of a business that employed 12 workers indicate that:

Business cost per month per worker x number of workers x number of months

= $55.25 to $110.50 x 12 x 12

= $7,956.00 to $15,912.00 per year

Or

Plant cost per month per worker x number of workers x number of months

= $110.50 to $221.00 x 12 x 12

= $15,912.00 to $31,824.00 per year

For any business this is a lot of money. So what is the potential saving minus the cost of this health and safety management software?

Paper based business cost per year – software based business cost per year

= ($18,360.00 to $32,639.00) – ($7,956.00 to $15,912.00)

= $10,404.00 to $16,727.00 business savings per year

Or

Paper based plant cost per year – software based plant cost per year

= ($36,720.00 to $65,279.52) – ($15,912.00 to $31,824.00)

= $20,808 to $33,355.52 plant saving per year

For businesses this is a saving of $72.25 to $116.15 per worker, per year. Moreover this saves $144.50 to $231.63 for each worker a year.

The potential savings calculated here do not include the cost of the risk assessment system but considering OHS laws and regulations aren’t going anywhere, you should view software as an investment. Once you have established the cost of the software system you intend to use, you can calculate your return on investment (ROI). We think you’ll be pleasantly surprised. In the meantime you can read more about how SafeWorkPro’s job safety analysis software can cut your costs and boost productivity.