How a Simple Process Drives Safety Compliance

Safety management systems have come a long way in the last 250 years. Just think back to workplace conditions during the Industrial Revolution – almost no pay, child labour, very long hours, and extremely dangerous work conditions with exposure to chemicals, accident-prone machinery, and no WHS requirements whatsoever.

But this has changed over the years. Legal reforms and acts were introduced – the Factory Act, the Employer’s Liability Act, and finally, the 1974 Health and Safety at Work Act. This legal document became the foundation for workplace health and safety processes in the UK and the rest of the world. And it led to the increasingly more complex safety processes we have today.

The core purpose of WHS is to keep people safe. Simple. With the increasing complexity of requirements and standards, Business owners, project managers and safety officers alike have to be careful of falling into the trap of using compliance to document requirements like the SWMS as their main measure of WHS compliance. This article looks at why adhering to document requirements is a poor standalone indicator of compliance. We also suggest how a simple safety process drives the success of your WHS compliance.

Documents are Symbols of a Process

Safety isn’t symbolic. It is real and should be treated in the real world, not on a document. Safety management systems do involve documents, but they symbolise a process. For example, a SWMS is a safety planning tool that identifies the risks of high risk construction work and the actions taken to manage those risks. It symbolises the process you are going to take when dealing with the risks and making sure your workplace and its workers are safe from those risks. When it’s under the (judges) hammer, the process symbolised (documented) matters most – not the symbol or the document itself.

Downloading a generic template for your SWMS, JSA, or any other safety document is like taking the symbol without taking the process it represents. And that defeats the whole point of your safety management system and its documents. To comply with WHS requirements, you should be focusing on the processes required to keep your workplace and its workers safe – not just on the documents themselves.

WHS audits look at whether you have followed an effective process that actively reduces the risks in your workplace. They care about if you have actually provided a safe work environment. Not simply whether you have ticked the box of completing a piece of paperwork.

In 2013, The Supreme Court Qld in a case against a QLD construction company for the death of two workers cited:

“work practices focused too much on the work performed onsite and did not pay adequate attention to the dangers presented by the conditions of the site itself”

In other words, not considering risks on the ground, in the real world can have significant impacts when taken to the extremes. Focussing too hard on the details of the tasks to be completed can lead to ignoring all the risks that are actively present

What you focus on matters. And if you want to pass your WHS audit and actually keep your workers safe, then it’s time to focus on the safety management process behind the symbols and documents.

But I still go through a process when filling in a template?

Safety management systems aren’t just about the symbols. They’re about the processes behind them. But you may be wondering – isn’t downloading a generic template still technically a process? Sure. But think about this. What process is more effective at satisfying the Work Health and Safety Act requirement to provide a safe work environment? Is it:

- Find a generic SWMS template on Google, Officeworks or other source

- Complete the boxes provided by the template as best as you can

- Gather up or seek out workers individually and gather signatures

- Store it onsite until the work is done

- Transferring the document to a folder in your office when you are done with the site

Or:

- Identify a the risks onsite, in person

- Build a new SWMS or modify the existing version to cover all task & site-specific risks that are present. Pushed to everyone to sign.

- Monitor how measures are being implemented while work is being completed with real time automated risk rating notifications

- Review by anyone relevant once the work has been completed

- Automatic document storage once complete for any future audits, follow-ups, or learning

From a legal standpoint, the second option is better,

The very purpose of developing a SWMS is to ensure that employers and workers have taken the time to identify the high-risk tasks to be done on site. And then, it is to develop measures to manage these risks and tasks in the context of the work being done. The very nature of a SWMS is that it is specific. It is created specifically in response to a specific site, specific tasks, and specific risks. A generic templated SWMS will not meet the intention behind WHS requirements. Instead, it will defeat the real power of the SWMS and even take away from your safety management.

As WorkSafe Victoria explains, “our concern is not what is written but what actually happens”. A generic SWMS is a symbol of safety that only provides guidance. To focus on the process and comply with WHS requirements, your SWMS and other safety documents need to be customised. It is the second process that is more likely to pass a WHS audit because it demonstrates an active approach to creating a safe work environment. And it is the first process that will get a much more severe punishment when a safety incident does happen, even though both processes are represented by the same type of document.

How to Prioritize the Process

The simplest way to boost the effectiveness of your safety process is to use a digital safety platform like SafeWorkPro. While you can do your safety management physically or digitally, doing it digitally is what will make the difference. Why?

Safety management software simplifies your safety management. Turning a complex process into a simple, easy to understand workflow that allows for an easier way to assess, mitigate, monitor and review workplace risks of all nature. It makes sure that your safety management system is customised, comprehensive, and lets you focus on the process. Leave the document creation, distribution and storage to the software. With safety management software, you can seamlessly customise, prioritise, and ensure your safety management system and its processes exceed WHS regulations.

SafeWorkPro is the Australian safety management software that can make sure your workplace prioritises the process over the symbols.

- Customise your SWMS, JSA, or other safety documents specifically to your worksite using our flexible document builder

- Make sure your specific workplace risks are managed and your workers are safe

- Ensure your company truly complies with WHS requirements

Do all of this seamlessly and in one place with the SafeWorkPro platform. Click the button below to find out more.

More From The SafeWorkPro Blog

Why Should You Keep Records of Risk Assessment Reports?

There are two answers to this question. First of all, creating safety culture within all aspects of the Australian workforce is the purpose of risk assessment. So by keeping records of completed risk assessments you have documents to refer back to for help with future health and safety tasks. This is useful for normalising a culture of workplace safety. The second reason for keeping risk assessment records is far more pragmatic.

The Work Health and Safety Act outlines the responsibilities duty holders have in creating and maintaining a safe workplace. Keeping records of risk assessments indicates potential compliance with these laws and can help ensure businesses do not get stung with hefty penalties.

Keeping records of the risk management process has many benefits. These include:

- Demonstrates to customers, clients, regulators and other business associates that health risks at work are being managed effectively

- A risk assessment review can be conducted more easily, resulting in greater business flexibility should OHS laws and regulations change

- Provides a base for preparing future safe operating procedures

- Allows more effective risk assessment training based on targeted goals

- Demonstrates how a person conducting a business of undertaking (PCBU) made risk management decisions

When keeping records of risk assessments, it’s useful to make special note of information like:

- Possible changes to either work practices or the workplace in general

- Any risk assessment training courses undertaken

- The parties that were consulted with during the risk management process

- When and how the risk assessment was implemented and reviewed

- The hazards and risks identified and the selected control methods

- Any complementary risk assessment forms including safety checklists, worksheets and risk assessment matrices

The scale and depth of maintaining risk assessment records may vary according to the size and nature of a business. In regards to a construction site risk assessment, there are certain requirements for how long risk assessments should be kept. Depending on the jurisdiction, risk assessment should be kept between five to seven years after a dangerous incident has taken place. Unless an incident has taken place, there is no minimum time period PCBU’s are required to keep records for but the practice is recommended nonetheless.

PCBU’s must also ensure all employees are aware of record keeping requirements including their locations and how to access them. For more information on record keeping for risk assessments read Safe Work Australia’s code of practice. Alternative you can read the SafeWorkPro Blog for answers to more basic risk assessment questions.

How much does paper-based risk assessments cost your business?

Every business risk is different but if you take an average value on the cost associated with each part of the risk analysis process, you’ll get a fair idea about how inefficient the paper-based method actually is. The data presented here was taken by surveying a construction business of 12 workers and represents a significant part of our broader risk assessment productivity case study. The average time spent on risk assessment processes per job is:

Avg job time = 9 to 16 mins (for more information in time calculations read here)

Avg no. of jobs per worker, per month = 20 jobs

Therefore to calculate the amount of time spent in a month for each worker:

Avg job time x avg jobs per month

= 9 to16 mins x 20 jobs

= 180 to 320 mins per month

= 3 to 5.3 hours per month

So we know that for a business of 12 workers, around three to five hours a month is spent completing risk assessment sheets. Depending on where the invoices and time sheets are considered, the costs will be on either the contractor’s business or the plant they work for. In these following calculations we include both costs to show a comparison. The average cost of a worker is:

Avg cost to business = $42.50/hour (Hour much you pay your workers)

Or

Avg cost to plant = $85/hour (How much you charge for your workers)

Therefore to calculate the amount of money spent in a month for a single worker:

Avg cost to business x hours per month

= $42.50 x 3 to 5.3

= $127.50 to $226.66 business cost per month, per worker

Or

Avg cost to plant x hours per month

= $85.00 x 3 to 5.3

= $255.00 to $453.33 plant cost per month, per worker

When you spread these numbers over a 12-month period, it becomes clear just how much money is spent conducting a risk assessment. For a construction contracting business in this survey that has 12 workers the annual cost is:

Business cost per month per worker x number of workers x number of months

= $127.50 to $226.66 x 12 x 12

= $18,360.00 to $32,639.00 per year

Or

Plant cost per month per worker x number of workers x number of months

= $255.00 to $453.33 x 12 x 12

= $36,720.00 to $65,279.52 per year

No matter how you change the numbers associated with your business there is no getting away from the underlying cost that a risk assessments and SWMS’s related processes have on your business. These approximate calculations do not include the time spent in administration of creating and maintaining a set of SWMS’s that a QTP (Qualified Trade Person) must sign-off. So, how can you reduce this cost? We believe the answer lies in business automation using software-based systems.

The Health Risks of Asbestos Poisoning

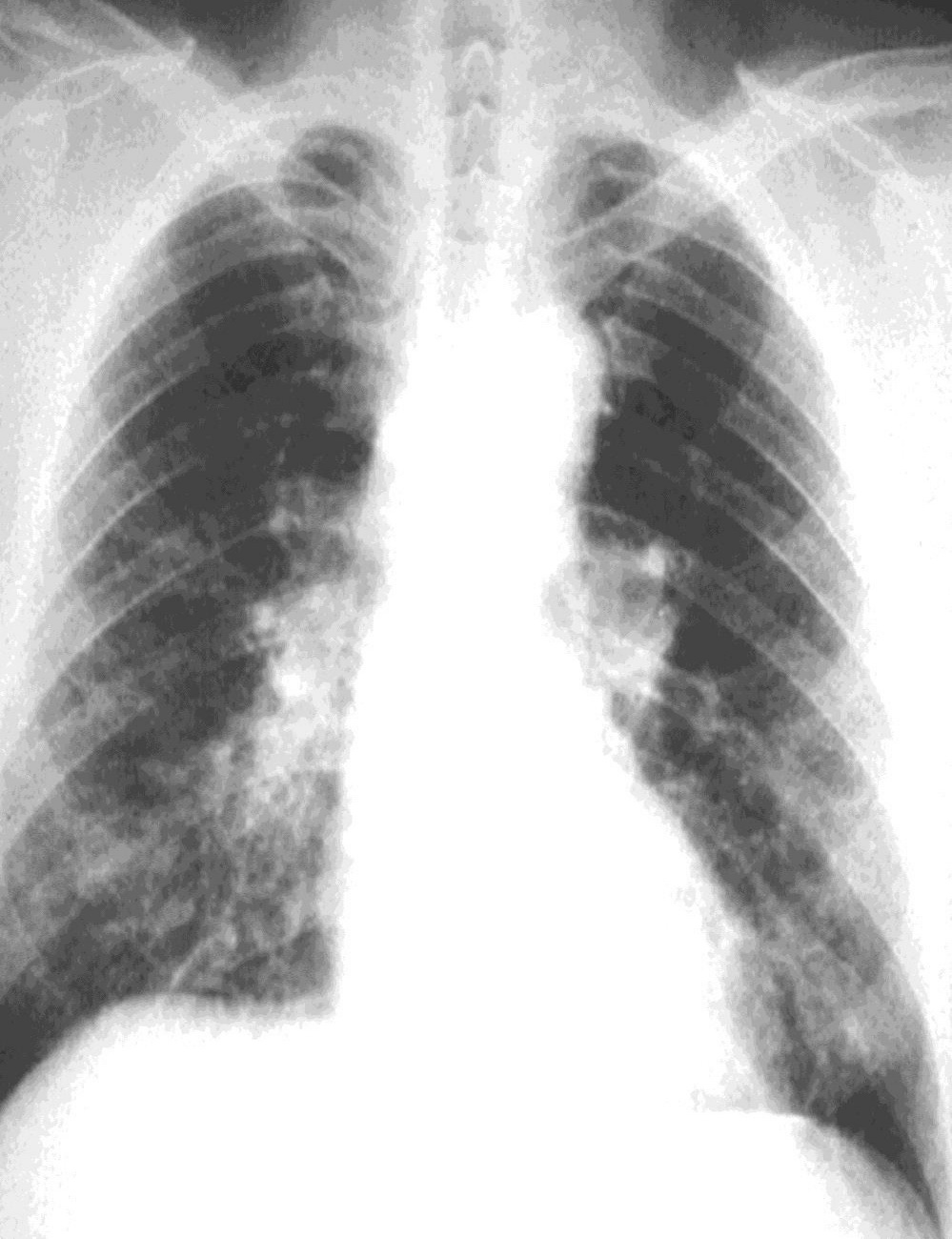

Asbestosis

What is it?

Asbestosis is an incurable lung disease characterised by the scarring of lung tissue caused by the inhalation of asbestos fibres. Unlike lung cancer or mesothelioma, people with asbestosis can live for decades after diagnosis but as time passes, the individual’s condition will deteriorate and require more treatment.

Symptoms:

Asbestosis is caused by sharp, minuscule asbestos fibres becoming lodged in the lung tissue. Over the period of 20 to 30 years, the fibres cause inflammation and eventually scarring as the body attempts to heal. The severity of the symptoms depends of the length of an individual’s exposure to asbestos and include:

- Swelling in the face and neck

- Shortness of breath and coughing

- Chest pain

- Loss of appetite and weight loss

- Swallowing difficulties

- Blood in the lung mucus (sputum)

- Crackling noise in breathing

- High blood pressure/hyper tension

- Deformed fingers

Treatment:

Due to the fact that no cure currently exists for asbestosis, the treatment methods commonly offered are designed to manage the symptoms rather than treat the cause. Along with healthier lifestyle and diet changes, supplemental oxygen and antibiotics, several treatment options are available for sufferers of asbestosis.

- Pulmonary rehabilitation: a long-term treatment that teaches better breathing methods, exercise techniques and stress relief.

- Prescription medications that ease pain and dilute secretions.

- Respiratory physiotherapy to remove lung secretions

For more information on asbestosis, check out the Australian Asbestos Network.

Benign Pleural Disease

This is the most common form of disease found in people that have been exposed to asbestos. Benign pleural diseases are usually not life threatening but can cause extreme discomfort and pain, and can be symptomatic of late stage mesothelioma. The four main types of asbestos related pleural disease include:

- Pleural plaques: these are patches of fibrous thickening that develop between the rib bones and the lining of the lung. Plaques are generally not viewed as a serious health issue but can cause painful and difficult breathing patterns.

- Pleural effusions: this occurs when fluid is leaked into the space between the lung and the membrane that lines it. Although not life threatening on its own, pleural effusions cause extreme chest pain can reoccur even after treatment.

- Pleural thickening: this is when the lining of the lung tissue becomes irritated resulting in lesions and swelling. In unusual cases, pleural thickening can be life threatening as it severely disrupts breathing patterns.

- Pleuritis: this occurs after the lining of the lung tissue (pleura) becomes inflamed causing significant chest and shoulder pain.

In most cases the best treatment for pleural disease is lifestyle changes (ie quitting smoking) and appropriate exercise. If you are experiencing any of these symptoms you should contact your doctor immediately as it may be indicative of lung cancer.

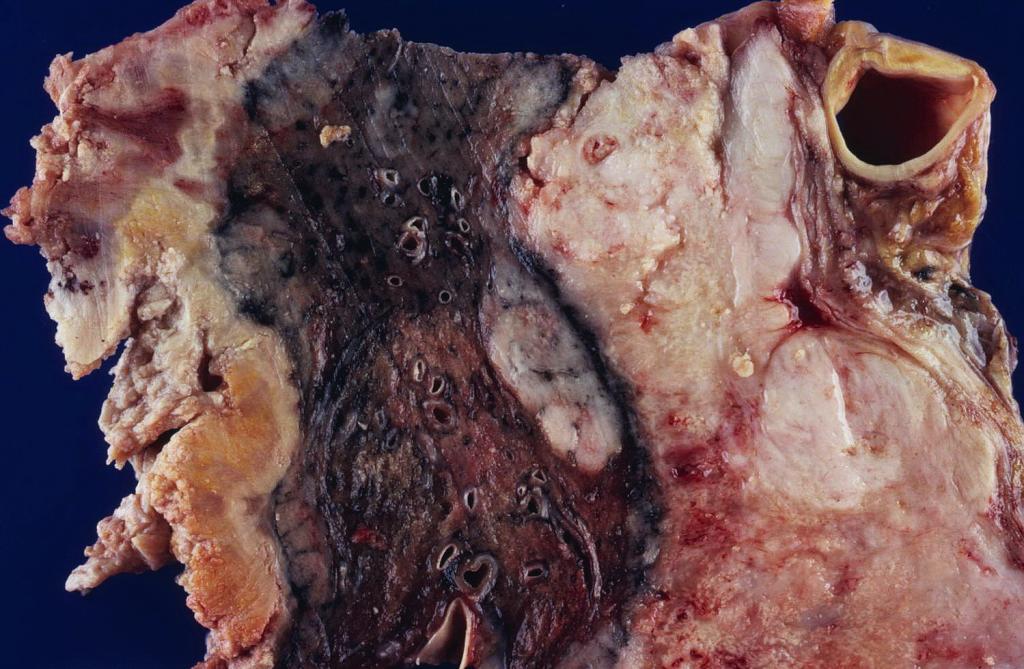

Mesothelioma

What is it?

Mesothelioma is a form of cancer that can take anywhere between 20 and 50 years to display symptoms. It is caused by asbestos fibres that become lodged in the tissue surrounding the lungs, resulting in cellular damage that eventually leads to tumour growth. This is known as pleural malignant

mesothelioma and represents the most common form of this disease. However asbestos inhalation can also cause this cancer to occur in the lining of the abdominal cavity (peritoneal) and the heart (pericardial).

Symptoms:

The different forms of mesothelioma have varying symptoms of which more information can be found out about here. Symptoms, even those displayed in the later stages of the disease’s progression, can be subtle and unnoticeable. Early signs can be so insignificant that even doctors can misinterpret them as a simple ache or illness. The most common symptoms for mesothelioma include:

- Constant fatigue

- Loss of appetite and weight loss

- Chest pain

- Breathing difficulties

- Dry coughing

- Shortness of breath

Current medical research is aimed at finding earlier diagnosis systems but there are several more symptoms that indicate mesothelioma has spread to other parts of the body. These symptoms include:

- Difficulty swallowing

- Obstruction of the superior vena cava (a vessel that carries blood into the heart) leading to shortness of breath and facial swelling

- Low blood sugar levels (hypoglycaemia)

- Damage to nerves attached to voice box (laryngeal) leading to harsh breathing and speaking

Treatment:

Currently no cure for mesothelioma exists but there several treatment options available that can alleviate symptoms and extend life expectancy.

- Surgery: this treatment method can be used to remove tumours, alleviate pain for improved quality of life or to secure a biological sample for diagnosis.

- Chemotherapy: a chemical infusion into the bloodstream that aims to kill cancer cells, reduce the size and spread of tumours and prolong survival. Unfortunately chemotherapy cannot cure mesothelioma and comes with significant side effects including hairs loss, nausea and weight loss.

- Radiation therapy: this is used to stunt the growth of tumours and has been known to increase life expectancy and alleviate pain. Radiation therapy can be used at any stage of mesothelioma and includes the side effects of skin irritation, inflammation of the oesophagus, fatigue and nausea.

Beside mesothelioma and lung cancer, asbestos poisoning has been linked to the following cancers:

- Prostate

- Gallbladder

- Hodgkin’s lymphoma

- Non- Hodgkin’s lymphoma

- Kidney

- Leukemia

- Gastrointestinal

- Colorectal

- Laryngeal

- Breast

- Ovarian