3 Signs Safety Software Might Be The Solution For You

Safety software is a relatively new solution to an old problem. Have you ever thought to yourself, there has got to be a better way to stay complaint with safety regulations? Do you ever get frustrated that you have to fill out so many assessments and statements on paper. Do you find yourself missing things in your assessments because you are worried that it’s not in the right format?

These are just some of the frustrations that come with the process of staying compliant with safety regulations. It can have significant effects on your safety culture if you find the process of safety too difficult. If you have ever ran into any of the above, it might be time to consider finding a solution before it becomes too much of a headache that safety goes out the window and all your effort is spent just to be compliant.

In this article we will cover in depth 3 signs that it might be time to consider utilizing safety software before your safety is ignored for compliance.

You’re worried about compliance incase of an incident

Running a business is no easy task. It’s like juggling 10 things at once. When things are going well, it’s a great feeling. But it only takes one slip up or incident to cause everything to come crumbling down. The stress and anxiety of a WHS incident happening in your business is enough to keep anyone up at night. On top of that, if you know you might get slapped with a fine after the incident you’ll always be stressed or worse, you’ll delay reporting an incident. This can lead to huge fines and even jail time. No one wants that.

Safety compliance in the modern day is no simple task. There are a lot of regulations and legislation that you must adhere to in your day to day business. This can become quite a headache and adds to the stress of making sure you have ticked all the boxes. Or worse, leads you to ignoring your requirements and hoping that an incident doesn’t occur. As we have covered in a previous article, incidents happen to even the best of employers who are proactive with safety, its simply the reality of probability. If there is a chance, eventually it will happen.

Ask yourself this. If there was an incident at your workplace tomorrow and it lead to an inspection, would you be confident you would pass? Have you got a solid and refined risk assessment process in place to identify, assess and control risks in your workplace?

If the answer is not a confident yes then it might be time to look at solutions. Safety software like our platform SafeWorkPro allows you to focus on your process more while making the document compliance side of things a worry of the past. While SafeWorkPro won’t solve all of your safety worries, it will help you be more effective with your time so you can spend less time filling out forms and more time focusing on the actions that lead to a safer workplace. We have talked about how your process is more important than your documents in a previous article. In the eyes of the law, the concern is about what you actually do to keep people safe.

If you want to spend more time on safety and less time on the books, then safety software might be the solution for you.

Safety software makes documentation simple and easy

How long does it take you to complete a risk assessment from start to finish? What about a SWMS? Do you find it difficult to complete documents because of all the back and forth that is required between the site, office and in between your workers? If your documentation process is top notch and you have no issues with filling out lengthy paper documents then this might not apply to you. But for those that get frustrated with how much time away from work they have to take to complete documents, this one might be for you.

When the bottle neck for starting a job is the paperwork you need to complete for safety compliance it can become frustrating. It can sometimes feel like too much time is being wasted on paperwork when you could be working. This can lead to rushing through it which defeats its purpose. It also means that you are more likely to skip the processes that really matter to keep people safe.

If you are on a site that needs a SWMS and something changes that requires you to re-evaluate your SWMS, the process starts again and the tools are down until it is done. With safety software, the process of completing documentation is significantly easier. In principle, it is the same but in practice you’re saving time that would otherwise be spent filling a document and running around to get it signed. SafeWorkPro’s simple form based builder allows you to build custom documents which are super simple for your workers to complete on site when needed.

Save the hassle of the back and forth trying to get your documents read and signed by those on site. Have workers fill and sign documents from anywhere on site and have them submitted to the cloud for you to review from any location. SafeWorkPro even lets you get notifications when certain actions happen like a risk rating on a risk assessment matrix being too high or an incident is submitted. SafeWorkPro can help you save time on compliance and let’s you focus on what you do best.

Safety software helps you find old documents quick

Ask yourself this, can you find your risk assessment or SWMS from a job 2 years ago? If you were audited, could you produce it? This is something that isn’t obvious until it is an issue and by then it’s too late. How much of an impact on your day to day operations would a surprise audit have? Would you need to go digging through the back office folders to find the documents required? What a headache!

Even while you are on site, your documents like a SWMS need to be available for everyone to see. While they are there, they are likely to get damaged or degraded by weather. Sometimes, by the time they get stored for safe keeping they are almost falling apart.

With the safety of cloud document storage, SafeWorkPro can store all of your important documents online forever. With all of your documents in one place and neatly organized it’s super simple to find the documents you need, even if they are from years ago. Our software also makes audits quick and easy with next to no disruption in your operations. Export all of the data from your SafeWorkPro site for review without having to spend hours digging through folders, photocopying and physically delivering documents.

Conclusion

If any part of this article resonates with you, it might be time to consider trying out a better solution to using a manual safety process. Beyond just the convenience, SafeWorkPro can help you focus your time on the actions that truly make people safe, not just the actions that make you compliant. At the end of the day, that is what you will be judged on if you have an audit or investigation. Documentation is required of course, but that is simple the surface level when it comes to safety.

If you want to learn more about how SafeWorkPro could help you in simplifying your WHS, reach out to our friendly expert staff for a free, no obligation live demo.

Why Should You Keep Records of Risk Assessment Reports?

There are two answers to this question. First of all, creating safety culture within all aspects of the Australian workforce is the purpose of risk assessment. So by keeping records of completed risk assessments you have documents to refer back to for help with future health and safety tasks. This is useful for normalising a culture of workplace safety. The second reason for keeping risk assessment records is far more pragmatic.

The Work Health and Safety Act outlines the responsibilities duty holders have in creating and maintaining a safe workplace. Keeping records of risk assessments indicates potential compliance with these laws and can help ensure businesses do not get stung with hefty penalties.

Keeping records of the risk management process has many benefits. These include:

- Demonstrates to customers, clients, regulators and other business associates that health risks at work are being managed effectively

- A risk assessment review can be conducted more easily, resulting in greater business flexibility should OHS laws and regulations change

- Provides a base for preparing future safe operating procedures

- Allows more effective risk assessment training based on targeted goals

- Demonstrates how a person conducting a business of undertaking (PCBU) made risk management decisions

When keeping records of risk assessments, it’s useful to make special note of information like:

- Possible changes to either work practices or the workplace in general

- Any risk assessment training courses undertaken

- The parties that were consulted with during the risk management process

- When and how the risk assessment was implemented and reviewed

- The hazards and risks identified and the selected control methods

- Any complementary risk assessment forms including safety checklists, worksheets and risk assessment matrices

The scale and depth of maintaining risk assessment records may vary according to the size and nature of a business. In regards to a construction site risk assessment, there are certain requirements for how long risk assessments should be kept. Depending on the jurisdiction, risk assessment should be kept between five to seven years after a dangerous incident has taken place. Unless an incident has taken place, there is no minimum time period PCBU’s are required to keep records for but the practice is recommended nonetheless.

PCBU’s must also ensure all employees are aware of record keeping requirements including their locations and how to access them. For more information on record keeping for risk assessments read Safe Work Australia’s code of practice. Alternative you can read the SafeWorkPro Blog for answers to more basic risk assessment questions.

How much does paper-based risk assessments cost your business?

Every business risk is different but if you take an average value on the cost associated with each part of the risk analysis process, you’ll get a fair idea about how inefficient the paper-based method actually is. The data presented here was taken by surveying a construction business of 12 workers and represents a significant part of our broader risk assessment productivity case study. The average time spent on risk assessment processes per job is:

Avg job time = 9 to 16 mins (for more information in time calculations read here)

Avg no. of jobs per worker, per month = 20 jobs

Therefore to calculate the amount of time spent in a month for each worker:

Avg job time x avg jobs per month

= 9 to16 mins x 20 jobs

= 180 to 320 mins per month

= 3 to 5.3 hours per month

So we know that for a business of 12 workers, around three to five hours a month is spent completing risk assessment sheets. Depending on where the invoices and time sheets are considered, the costs will be on either the contractor’s business or the plant they work for. In these following calculations we include both costs to show a comparison. The average cost of a worker is:

Avg cost to business = $42.50/hour (Hour much you pay your workers)

Or

Avg cost to plant = $85/hour (How much you charge for your workers)

Therefore to calculate the amount of money spent in a month for a single worker:

Avg cost to business x hours per month

= $42.50 x 3 to 5.3

= $127.50 to $226.66 business cost per month, per worker

Or

Avg cost to plant x hours per month

= $85.00 x 3 to 5.3

= $255.00 to $453.33 plant cost per month, per worker

When you spread these numbers over a 12-month period, it becomes clear just how much money is spent conducting a risk assessment. For a construction contracting business in this survey that has 12 workers the annual cost is:

Business cost per month per worker x number of workers x number of months

= $127.50 to $226.66 x 12 x 12

= $18,360.00 to $32,639.00 per year

Or

Plant cost per month per worker x number of workers x number of months

= $255.00 to $453.33 x 12 x 12

= $36,720.00 to $65,279.52 per year

No matter how you change the numbers associated with your business there is no getting away from the underlying cost that a risk assessments and SWMS’s related processes have on your business. These approximate calculations do not include the time spent in administration of creating and maintaining a set of SWMS’s that a QTP (Qualified Trade Person) must sign-off. So, how can you reduce this cost? We believe the answer lies in business automation using software-based systems.

The Health Risks of Asbestos Poisoning

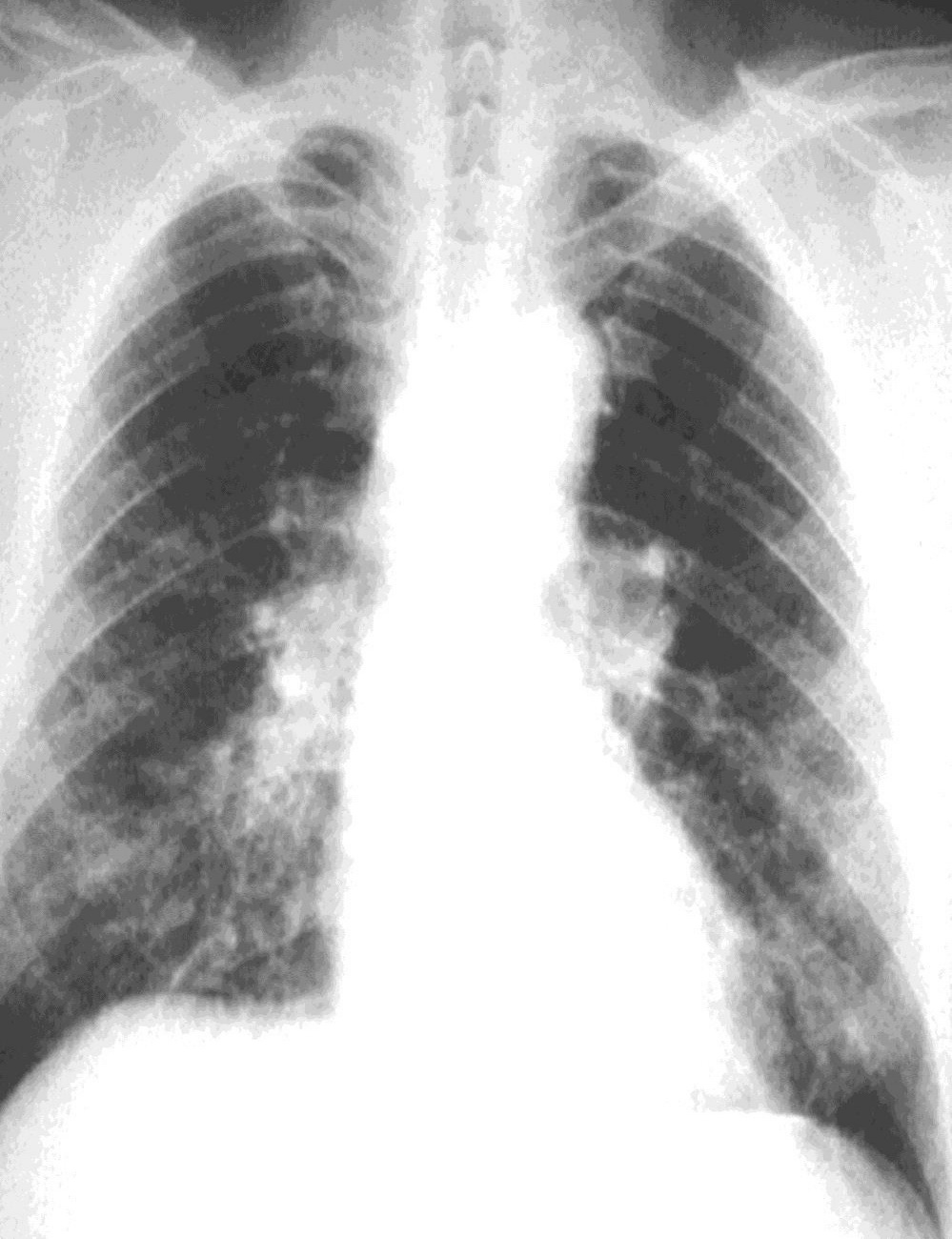

Asbestosis

What is it?

Asbestosis is an incurable lung disease characterised by the scarring of lung tissue caused by the inhalation of asbestos fibres. Unlike lung cancer or mesothelioma, people with asbestosis can live for decades after diagnosis but as time passes, the individual’s condition will deteriorate and require more treatment.

Symptoms:

Asbestosis is caused by sharp, minuscule asbestos fibres becoming lodged in the lung tissue. Over the period of 20 to 30 years, the fibres cause inflammation and eventually scarring as the body attempts to heal. The severity of the symptoms depends of the length of an individual’s exposure to asbestos and include:

- Swelling in the face and neck

- Shortness of breath and coughing

- Chest pain

- Loss of appetite and weight loss

- Swallowing difficulties

- Blood in the lung mucus (sputum)

- Crackling noise in breathing

- High blood pressure/hyper tension

- Deformed fingers

Treatment:

Due to the fact that no cure currently exists for asbestosis, the treatment methods commonly offered are designed to manage the symptoms rather than treat the cause. Along with healthier lifestyle and diet changes, supplemental oxygen and antibiotics, several treatment options are available for sufferers of asbestosis.

- Pulmonary rehabilitation: a long-term treatment that teaches better breathing methods, exercise techniques and stress relief.

- Prescription medications that ease pain and dilute secretions.

- Respiratory physiotherapy to remove lung secretions

For more information on asbestosis, check out the Australian Asbestos Network.

Benign Pleural Disease

This is the most common form of disease found in people that have been exposed to asbestos. Benign pleural diseases are usually not life threatening but can cause extreme discomfort and pain, and can be symptomatic of late stage mesothelioma. The four main types of asbestos related pleural disease include:

- Pleural plaques: these are patches of fibrous thickening that develop between the rib bones and the lining of the lung. Plaques are generally not viewed as a serious health issue but can cause painful and difficult breathing patterns.

- Pleural effusions: this occurs when fluid is leaked into the space between the lung and the membrane that lines it. Although not life threatening on its own, pleural effusions cause extreme chest pain can reoccur even after treatment.

- Pleural thickening: this is when the lining of the lung tissue becomes irritated resulting in lesions and swelling. In unusual cases, pleural thickening can be life threatening as it severely disrupts breathing patterns.

- Pleuritis: this occurs after the lining of the lung tissue (pleura) becomes inflamed causing significant chest and shoulder pain.

In most cases the best treatment for pleural disease is lifestyle changes (ie quitting smoking) and appropriate exercise. If you are experiencing any of these symptoms you should contact your doctor immediately as it may be indicative of lung cancer.

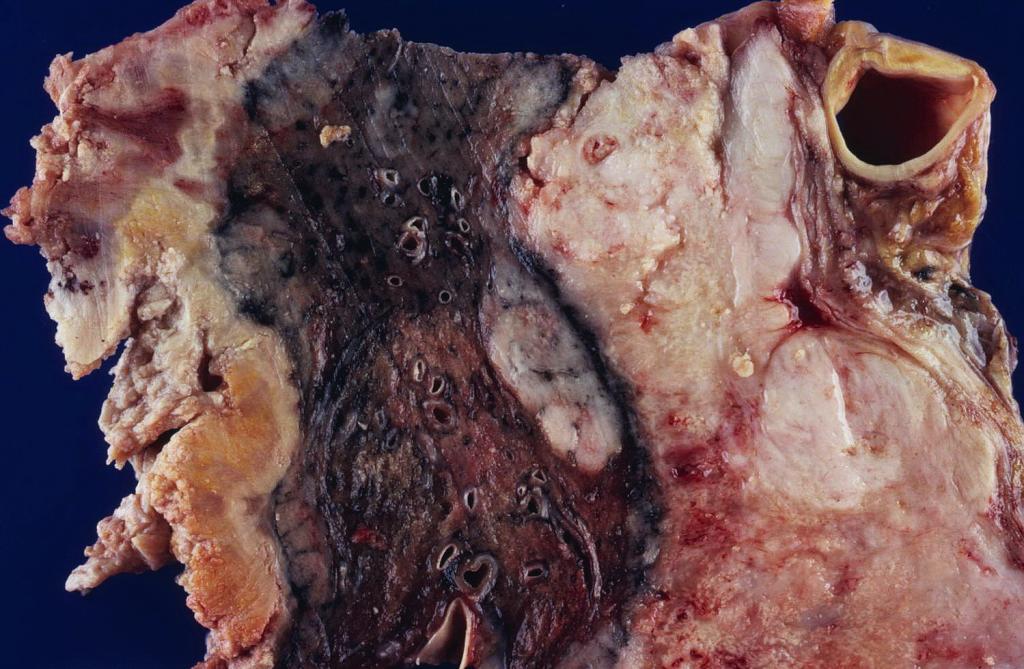

Mesothelioma

What is it?

Mesothelioma is a form of cancer that can take anywhere between 20 and 50 years to display symptoms. It is caused by asbestos fibres that become lodged in the tissue surrounding the lungs, resulting in cellular damage that eventually leads to tumour growth. This is known as pleural malignant

mesothelioma and represents the most common form of this disease. However asbestos inhalation can also cause this cancer to occur in the lining of the abdominal cavity (peritoneal) and the heart (pericardial).

Symptoms:

The different forms of mesothelioma have varying symptoms of which more information can be found out about here. Symptoms, even those displayed in the later stages of the disease’s progression, can be subtle and unnoticeable. Early signs can be so insignificant that even doctors can misinterpret them as a simple ache or illness. The most common symptoms for mesothelioma include:

- Constant fatigue

- Loss of appetite and weight loss

- Chest pain

- Breathing difficulties

- Dry coughing

- Shortness of breath

Current medical research is aimed at finding earlier diagnosis systems but there are several more symptoms that indicate mesothelioma has spread to other parts of the body. These symptoms include:

- Difficulty swallowing

- Obstruction of the superior vena cava (a vessel that carries blood into the heart) leading to shortness of breath and facial swelling

- Low blood sugar levels (hypoglycaemia)

- Damage to nerves attached to voice box (laryngeal) leading to harsh breathing and speaking

Treatment:

Currently no cure for mesothelioma exists but there several treatment options available that can alleviate symptoms and extend life expectancy.

- Surgery: this treatment method can be used to remove tumours, alleviate pain for improved quality of life or to secure a biological sample for diagnosis.

- Chemotherapy: a chemical infusion into the bloodstream that aims to kill cancer cells, reduce the size and spread of tumours and prolong survival. Unfortunately chemotherapy cannot cure mesothelioma and comes with significant side effects including hairs loss, nausea and weight loss.

- Radiation therapy: this is used to stunt the growth of tumours and has been known to increase life expectancy and alleviate pain. Radiation therapy can be used at any stage of mesothelioma and includes the side effects of skin irritation, inflammation of the oesophagus, fatigue and nausea.

Beside mesothelioma and lung cancer, asbestos poisoning has been linked to the following cancers:

- Prostate

- Gallbladder

- Hodgkin’s lymphoma

- Non- Hodgkin’s lymphoma

- Kidney

- Leukemia

- Gastrointestinal

- Colorectal

- Laryngeal

- Breast

- Ovarian