3 Signs Safety Software Might Be The Solution For You

Safety software is a relatively new solution to an old problem. Have you ever thought to yourself, there has got to be a better way to stay complaint with safety regulations? Do you ever get frustrated that you have to fill out so many assessments and statements on paper. Do you find yourself missing things in your assessments because you are worried that it’s not in the right format?

These are just some of the frustrations that come with the process of staying compliant with safety regulations. It can have significant effects on your safety culture if you find the process of safety too difficult. If you have ever ran into any of the above, it might be time to consider finding a solution before it becomes too much of a headache that safety goes out the window and all your effort is spent just to be compliant.

In this article we will cover in depth 3 signs that it might be time to consider utilizing safety software before your safety is ignored for compliance.

You’re worried about compliance incase of an incident

Running a business is no easy task. It’s like juggling 10 things at once. When things are going well, it’s a great feeling. But it only takes one slip up or incident to cause everything to come crumbling down. The stress and anxiety of a WHS incident happening in your business is enough to keep anyone up at night. On top of that, if you know you might get slapped with a fine after the incident you’ll always be stressed or worse, you’ll delay reporting an incident. This can lead to huge fines and even jail time. No one wants that.

Safety compliance in the modern day is no simple task. There are a lot of regulations and legislation that you must adhere to in your day to day business. This can become quite a headache and adds to the stress of making sure you have ticked all the boxes. Or worse, leads you to ignoring your requirements and hoping that an incident doesn’t occur. As we have covered in a previous article, incidents happen to even the best of employers who are proactive with safety, its simply the reality of probability. If there is a chance, eventually it will happen.

Ask yourself this. If there was an incident at your workplace tomorrow and it lead to an inspection, would you be confident you would pass? Have you got a solid and refined risk assessment process in place to identify, assess and control risks in your workplace?

If the answer is not a confident yes then it might be time to look at solutions. Safety software like our platform SafeWorkPro allows you to focus on your process more while making the document compliance side of things a worry of the past. While SafeWorkPro won’t solve all of your safety worries, it will help you be more effective with your time so you can spend less time filling out forms and more time focusing on the actions that lead to a safer workplace. We have talked about how your process is more important than your documents in a previous article. In the eyes of the law, the concern is about what you actually do to keep people safe.

If you want to spend more time on safety and less time on the books, then safety software might be the solution for you.

Safety software makes documentation simple and easy

How long does it take you to complete a risk assessment from start to finish? What about a SWMS? Do you find it difficult to complete documents because of all the back and forth that is required between the site, office and in between your workers? If your documentation process is top notch and you have no issues with filling out lengthy paper documents then this might not apply to you. But for those that get frustrated with how much time away from work they have to take to complete documents, this one might be for you.

When the bottle neck for starting a job is the paperwork you need to complete for safety compliance it can become frustrating. It can sometimes feel like too much time is being wasted on paperwork when you could be working. This can lead to rushing through it which defeats its purpose. It also means that you are more likely to skip the processes that really matter to keep people safe.

If you are on a site that needs a SWMS and something changes that requires you to re-evaluate your SWMS, the process starts again and the tools are down until it is done. With safety software, the process of completing documentation is significantly easier. In principle, it is the same but in practice you’re saving time that would otherwise be spent filling a document and running around to get it signed. SafeWorkPro’s simple form based builder allows you to build custom documents which are super simple for your workers to complete on site when needed.

Save the hassle of the back and forth trying to get your documents read and signed by those on site. Have workers fill and sign documents from anywhere on site and have them submitted to the cloud for you to review from any location. SafeWorkPro even lets you get notifications when certain actions happen like a risk rating on a risk assessment matrix being too high or an incident is submitted. SafeWorkPro can help you save time on compliance and let’s you focus on what you do best.

Safety software helps you find old documents quick

Ask yourself this, can you find your risk assessment or SWMS from a job 2 years ago? If you were audited, could you produce it? This is something that isn’t obvious until it is an issue and by then it’s too late. How much of an impact on your day to day operations would a surprise audit have? Would you need to go digging through the back office folders to find the documents required? What a headache!

Even while you are on site, your documents like a SWMS need to be available for everyone to see. While they are there, they are likely to get damaged or degraded by weather. Sometimes, by the time they get stored for safe keeping they are almost falling apart.

With the safety of cloud document storage, SafeWorkPro can store all of your important documents online forever. With all of your documents in one place and neatly organized it’s super simple to find the documents you need, even if they are from years ago. Our software also makes audits quick and easy with next to no disruption in your operations. Export all of the data from your SafeWorkPro site for review without having to spend hours digging through folders, photocopying and physically delivering documents.

Conclusion

If any part of this article resonates with you, it might be time to consider trying out a better solution to using a manual safety process. Beyond just the convenience, SafeWorkPro can help you focus your time on the actions that truly make people safe, not just the actions that make you compliant. At the end of the day, that is what you will be judged on if you have an audit or investigation. Documentation is required of course, but that is simple the surface level when it comes to safety.

If you want to learn more about how SafeWorkPro could help you in simplifying your WHS, reach out to our friendly expert staff for a free, no obligation live demo.

Risk Assessment For Working At Heights

Risks in construction are hard to pinpoint but working from heights is one of the more obvious hazards. Even you’re an expert tightrope walker, it’s an accident waiting to happen as are many things in high risk construction work. A simple hazard and risk identification process can prevent a dangerous fall but what should a safe work method statement for working at heights look like?

Every worksite is different so there is no common SWMS template that can be applied to all. However there are many core control methods that can show you how to manage risk at heights.

1: Never work alone: two sets of eyes are more powerful than one. If someone is working from heights, than they’ll need a pair of eyes on them to identify risks that could be otherwise missed.

2: Height safety training: learning about the specifics threats associated with working at heights is the first step to preventing them. Knowing what can go wrong will push workers to reach for those higher OHS standards.

3: Up to date equipment: having current inspection tags on all equipment will ensure that safe operating procedures are backed by reliable gear.

4: Double check anchor point and lanyard: the length of these must not exceed the impact point.

5: Finish the risk assessment form first: don’t gamble with the legal consequences of skimming past the OHS action plan. Hazard and risk assessment procedures must be completed before work begins otherwise all duty holders can become liable.

This is by no means an exhaustive list but if you’re looking for something more comprehensive, like a free SWMS template, you can check out the one developed by WorkSafePro. Let us know what you think on Facebook or Twitter.

Safety Rule This Summer: Under the hot summer sun, make safety priority number one

HEAT AND SUN SAFETY PLAN(5’S OF SUN SAFETY) Ultra-violet (UV) rays are deadly, so sun safety is vital in Queensland where the UV Index is three or above all year round. Outdoor workers must be supplied with sun protective clothing including a hat, sunscreen and sunglasses. You can also look at the possibility of rotating […]

Hazard management and risk assessment: what’s the difference?

They both sound like they mean the same thing but there is a difference between a risk and a hazard. Understanding this difference is an aspect of health and safety information that is all too often overlooked by workers and managers alike. In the field of occupational health and safety, this is but one of many basic risk assessment questions.

There is a difference and it is an important element to most hazard and risk assessment procedures. Based on Workplace Health and Safety Queensland’s codes of practice, the below definitions of risk and hazard are applicable to all Australian jurisdictions.

A hazard is a “situation or thing that has the potential to harm a person.” These can be aspects to a workplace like machinery, tools, vehicles or chemicals. Alternatively a hazard could include certain elements to a workplace like the repetitiveness of a job, bullying or violence.

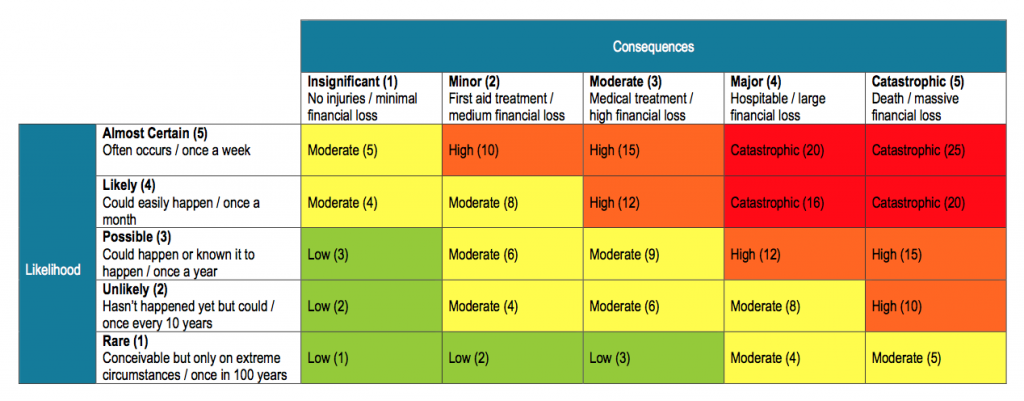

A risk is the likelihood of a person getting harmed (death, injury or illness) if they are exposed to a hazard. For construction workers, the level of risk associated with a hazard is determined by the completion of a risk assessment matrix (see image below).

Understanding the difference is obviously important in getting hazard and risk identification right in the workplace but it is also crucial for writing risk assessments. Risk control methods are based on accurate risk reporting and hazard identification meaning if done inconsistently, then the well being of workers is unnecessarily insecure.